Want to be part of the future?

Then sit back and learn about ETEKIN’s competitive advantages….

Competitive Advantage Nr.1

ETEKIN™ provides the world’s first 100% emission free, fully closed manure valorising technology reducing olfactory environmental burden and airborne disease spreading.

Manure is one of the most important sources of olfactory nuisance in intensively reared poultry operations Worldwide and has given rise to environmental concerns that are not only limited to the local production settings but extend to environmental problems at regional scales.

Together with the ever expanding poultry production and the consequent proximity of the latter with residential area’s the need for odourless or odour poor manure processing increases at a tremendous pace. In many regions in the world, in densely populated areas, odour nuisance has even become the limiting factor for production expansion.

Beside odour control, a fully closed system prevents spreading into the open of viral, bacterial and fungal agents and thus is a unneglectable part of disease control. Even the evaporated water is recuperated to the full extend. This water having a residual content of about 600ppm Nitrogen is ideal for irrigation means as such or can be treated by means of reverse osmosis reducing it to clean dischargeable water and concentrated liquid fertiliser.

Competitive Advantage Nr.2

ETEKIN guarantees the highest level of sanitization by reaching temperatures up to 135°C during 20minutes in the core of the material. At mentioned conditions, all residual infectious agents are 100% killed. No other manure treatment concept even comes near to that.

Infectious pressure control and sanitary surveillance has become a key issue in large poultry integrations. It has been shown extensively that manure can be a major carrier and reservoir of bacterial, fungal and viral diseases.

Important examples of diseases transmitted through poultry droppings are Newcastle disease1 and Avian Influenza. Other microbial agents present in poultry manure like Salmonella (2), Clostridium and E.coli(3)might present an even bigger risk for human infections.

Competitive Advantage Nr.3

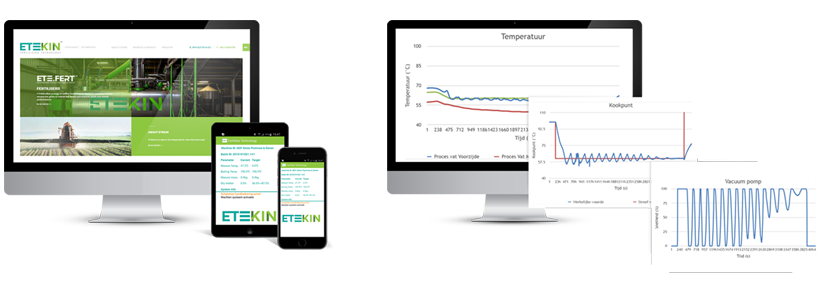

ETEKIN’s proprietary Organic Fertiliser Factory runs on in-house developed software, controlling the whole operation and offering maximal batch related traceability.

ETEKIN’s proprietary Organic Fertiliser Factory is a batch-based concept, not a continuous one. That means that batch after batch ( a batch consists of an input of 3tons of fresh manure) will be loaded and processed.

It is possible to track and trace each and every produced batch of fertiliser and also to compose custom specific fertilizer by adding this or that specific ingredient. Depending on the nature of the additive (for example heat resistant or not) this addition can be done during the feeding of the reactor or during the emptying of the same.

To allow maximal control, an Android App has been developed to inform the user in real-time about all data as described here above. As shown, each and every batch carries a unique batch number, allowing unseen traceability in our market segment.

Competitive Advantage Nr.4

ETEKIN’s Organic Fertiliser, because of its unique level of sanitation, responds to the most severe import regulations seen across the globe.

Because of its high level of sanitation, guaranteeing a 100% pathogen- and nematode- free status, the ETEKIN™ organic fertiliser is well appreciated in high value crops such as cut flowers, vegetables, ornamental plants, coffee and rice production, etc…

With only the water extracted, ETEKIN™ fertiliser holds way more nutrients than composted material because of absence of any form of bacterial breakdown.

Competitive Advantage Nr.5

ETEKIN provides world’s most compact manure valorising technology.

Because land, as any other resource, is a limited and therefore expensive asset, ETEKIN has chosen to build the most compact system for manure valorisation today available on the market

A single unit ETE.VAC™ driven Organic Fertiliser Factory can handle a daily amount of fresh manure (50% DM) and produce thus more than 3000 ton of high end organic fertiliser on a yearly basis on just 300m² of land.

Typical analysis

| Nitrogen Total (N) | 4.0% dm |

| Phosphorus (P2O5) | 3.0% dm |

| Potassium (K2O) | 2.4% dm |

| Carbon (C) | 35% dm |

| Sulfur (S) | 0.49% dm |

| C/N ratio | 8.8 |

| Boron (B) | 22 mg/kg dm |

| Copper (Cu) | 86 mg/kg dm |

| Iron (Fe) | 1500 mg/kg dm |

| Manganese (Mn) | 500 mg/kg dm |

| Molybdene (Mo) | <5.0 mg/kg dm |

| Zinc (Zn) | 380 mg/kg dm |

| Calcium (CaO) | 35.0 kg/ton |